Obtaining large-scale, efficient, high-precision machining in a short time ispossible thanks to multifunction units such as the WFL M65 Millturn. This lathe-milling unit easily processes 2000mm long shafts, but with thesupport of steady rests and tailstocks it can perform turning operationseven on pieces up to 4.500mm long. Furthermore, the possibility of exploiting 5-axis machining allows to obtain finished pieces faster than standard machining, which usually involves further milling phases.

Market competitiveness, speed and precision are all encapsulated in a single process: this is the perfect way to meet the needs of today’s working activities. Further information on the website https://www.viemmesrl.com/

5-axis CNC machining

Mori Seiki NT is equipped with 2 spindles and 2 turrets both capable of performing turning and milling operations. This equipment, through the 5 axis machining, allows the operator to carry out very complex jobs such as crankshafts or turbines with great precision, up to a maximum diameter of 300mm and a length of 400mm.

ViEmme SRL is a reference in precision machining, can perform large mechanical machining, has 6-axis CNC machining centers. Further information on the website https://www.viemmesrl.com

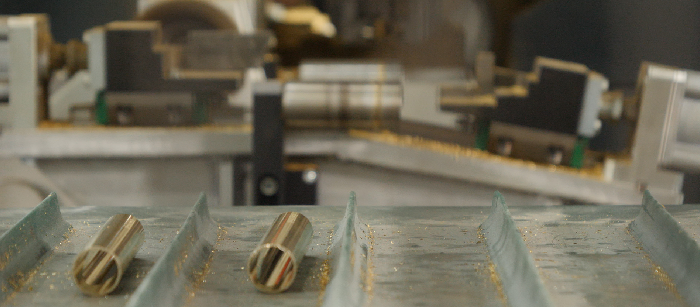

Automated Turning Department

These machines are one of the gems of ViEmme SRL. They are suitable for turning high quantities of pieces with diameters ranging from 40mm to 140mm.

Their strength comes from the fact that they are equipped with a programmable robot which can load/unload the pieces to facilitate the operator’s work by increasing efficiency to very high levels.

ViEmme SRL is a reference in precision machining, can perform large mechanical machining, has 6-axis CNC machining centers.

6-axis CNC machining

These 2 milling machines constitute a respectable work island and are the spearhead of ViEmme SRL.

They’re the flagship of ViEmme SRL. These two milling machines represent a remarkable work unit for ViEmme SRL. They can process pieces with maximum dimensions of 700mm in length, 700mm in width and 700mm in height; and perform complex 6-axis machining and deep drilling.

They feature two switchable pallets, and can machine a piece in a limited amount of steps, decreasing the processing time and thus making ViEmme SRL extremely competitive in the market.

Further information on the website www.viemmesrl.com .

Automated vertical warehouse

ViEmme SRL has 3 vertical automatic warehouses for the storage of the final products.

In the main site (called ViEmme 1) there is the warehouse called Lista, it is a single bay one, it is 6 meters high and it has 50 trays (more than 2 and a half meters wide). In the second location (ViEmme 2) there are 2 warehouses called Modula which have double bays. They are 8 meters high and have more than 50 trays each.

In just over 29 m³ all ViEmme products find an orderly and clean location; using a dedicated software it is possible to consult and manage the codes for loads / withdrawals and stock control. Furthermore, interfacing with the management software allows you to prepare the goods to be sent automatically and precisely.

ViEmme is a leading company in precision machining, it can process large part machining and has 6-axis CNC machining.

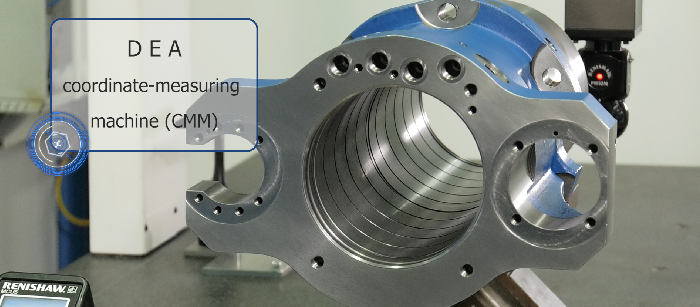

Measurement tools

ViEmme SRL is specialized in high precision machining and, in order to maintain high standards, it needs high-level measurement and quality control tools.

The high quality is achieved through periodic checks and reviews of all measuring instruments by specialized companies.

A metrology room has been set up inside the plant with a set temperature below 20 °C. All the measuring instruments are kept in the room and the most complex pieces are checked by a three-dimensional contact misuring machine, DEA, which detects the various dimensions of the sample; this machine allow to check simple diameters, flatness and concentricity, it records all the data in a report that guarantees to the customer quality and reliability.

For the control of high volume series ViEmme SRL relies on a statistical dimensional check by the operators and optical measuring machines. Even in this case all the appropriate measures are recorded in reports that create statistics for the improvement of the production and the maintaining of an high quality.

ViEmme SRL is a reference in high precision machining, able to perform large part machining, and has 6-axis CNC machining centers.

Machining per customer requirements

To meet customer needs, Viemme has designed work islands with custom-made and designed machinery. The aim is to carry out machining per customer requirements, creating numerous series products while standardizing the process as much as possible.

The automation of these machines, made ad hoc, allows to obtain a quality and efficiency corresponding to the customers’ wishes. The product becomes more competitive ensuring greater economic savings.

Viemme is a reference in high precision machining, able to performlarge part machining, and has 6-axis CNC machining centers. Further information on the website www.viemmesrl.com

Precision mechanical machining

The Viemme’s fleet has changed a lot over the years, modernizing in order to keep up with times. Viemme went through a natural evolution from the classic 2 or 3 axis machines up to 4, 5 and even 6 axis.

Company philosophy requires machinery capable of making complex and high quality pieces with few work steps. To achieve these results, it is necessary to use cutting-edge technologies that reduce the length of production processes and costs, satisfying the customer thanks to short delivery times.

Multus B400 is the ultimate mix of the turning operations, allowing precision mechanical machining per customer requirements both way, vertical and horizontal one. It is a CNC machine that performs process-intensive machining by effectively using the space.

Thanks to Thermo-Friendly construction, high precision is guaranteed even in the most complex applications.

Viemme is a leading company in precision mechanical machining, it can process large part machining and has 6-axis machining.

Large part machining

WFL M65 Millturn is a lathe-milling unit able (capable) of performing precision mechanical machining. It is ideal for machining with a maximum diameter of 730 mm and a length up to 4500 mm, it creates a wide range of types of items: from eccentric shafts to gears using processes such as deep drilling, slotting or toothing.

It is a versatile machine that guarantees a very high precision of the workpiece without having to use an external measurement tool. This is made possible thanks to the internal measurement system.

The WFL M65 summarizes all the phases that a single piece can be subjected to during its manufacturing cycle, with a reduced number of placements and maintaining exceptional quality.

Purchased in late 2015, this 5 axis machining center can support up to 4500 kg.

Viemme is a leading company in precision machining. It can process large part machining and has6-axis CNC machining.