ViEmme SRL is specialized in high precision machining and, in order to maintain high standards, it needs high-level measurement and quality control tools.

The high quality is achieved through periodic checks and reviews of all measuring instruments by specialized companies.

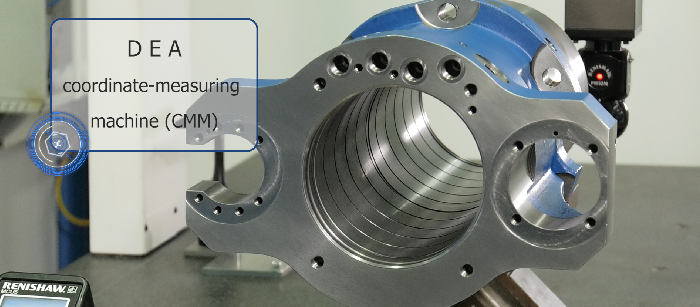

A metrology room has been set up inside the plant with a set temperature below 20 °C. All the measuring instruments are kept in the room and the most complex pieces are checked by a three-dimensional contact misuring machine, DEA, which detects the various dimensions of the sample; this machine allow to check simple diameters, flatness and concentricity, it records all the data in a report that guarantees to the customer quality and reliability.

For the control of high volume series ViEmme SRL relies on a statistical dimensional check by the operators and optical measuring machines. Even in this case all the appropriate measures are recorded in reports that create statistics for the improvement of the production and the maintaining of an high quality.

ViEmme SRL is a reference in high precision machining, able to perform large part machining, and has 6-axis CNC machining centers.